Requested Content Not Found

The page or file you requested could not be found.

Maybe you were looking for:

Modbus Device Connector

Easily read and write data to Modbus devices over both TCP and serial networks with IOTech's high-performance Modbus device connector.

Device Connectivity & the Edge in Resource-Constrained Situations

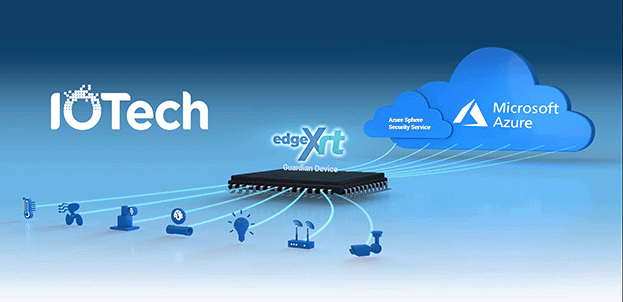

IOTech recently launched Edge XRT, a time-critical edge platform for Microsoft Azure Sphere, a secured, high-level application platform. Read more here.